Ya-VA Pallet Conveyor System Roller Chain idler Unit

Lintlha tsa Bohlokoa

| Boemo | E ncha |

| Tiisetso | 1 Selemo |

| Liindasteri tse sebetsang | Mabenkele a liaparo, Mabenkele a thepa ea kaho, Mabenkele a Tokiso ea Mechini, Setsi sa Tlhahiso, Feme ea Lijo le Lino, Tšebeliso ea Lehae, Mabenkele, Mabenkele a Lijo, Mabenkele a Khatisong, Mabenkele a Lijo le Lino |

| Boima (KG) | 0.92 |

| Sebaka sa Showroom | Viet Nam, Brazil, Indonesia, Mexico, Russia, Thailand, Korea Boroa |

| Tlhahlobo ea video e tsoang | Fanetsoe |

| Tlaleho ea Teko ea Mechini | Fanetsoe |

| Mofuta oa Papatso | Sehlahisoa se Tloaelehileng |

| Sebaka sa Tšimoloho | Jiangsu, China |

| Lebitso la Brand | YA-VA |

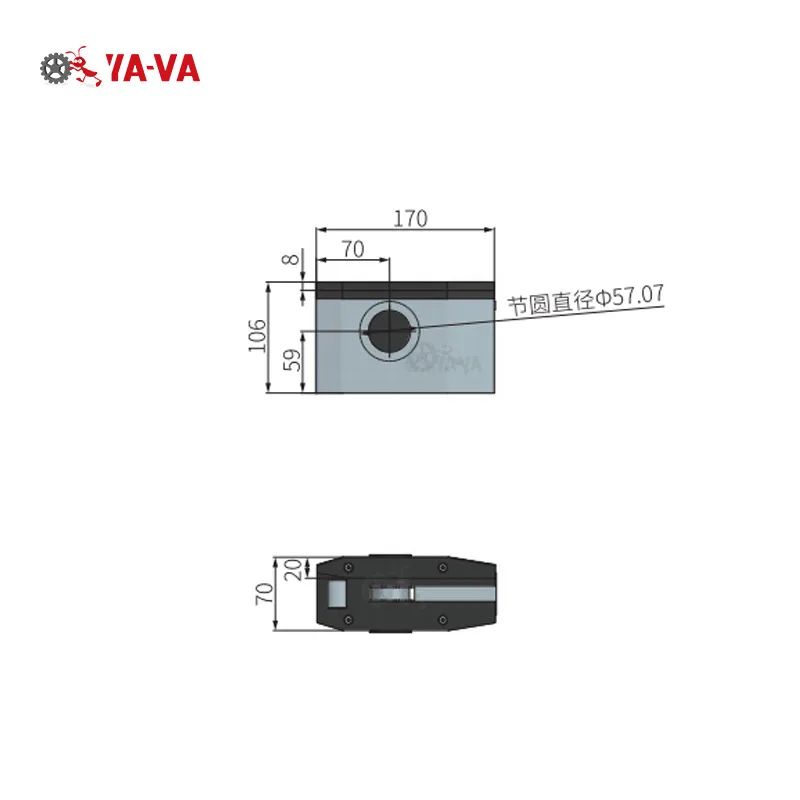

| Lebitso la sehlahisoa | Setsi sa Idler bakeng sa ketane ea roller |

| Bolelele ba pina bo sebetsang | 310 limilimithara |

| Boemo ba lebota | leqele / le letona |

| Lentsoe la sehlooho | tsamaiso ea pallet conveyor |

| Lintho tse bonahalang tsa 'mele | ADC12 |

| Khanna shaft | Zinc e koahetsoeng ka tšepe ea carbon |

| Drive sprocket | Tšepe ea carbon |

| Apara strip | Antistatic PA66 |

| Mmala | Ntsho |

Tlhaloso ea Sehlahisoa

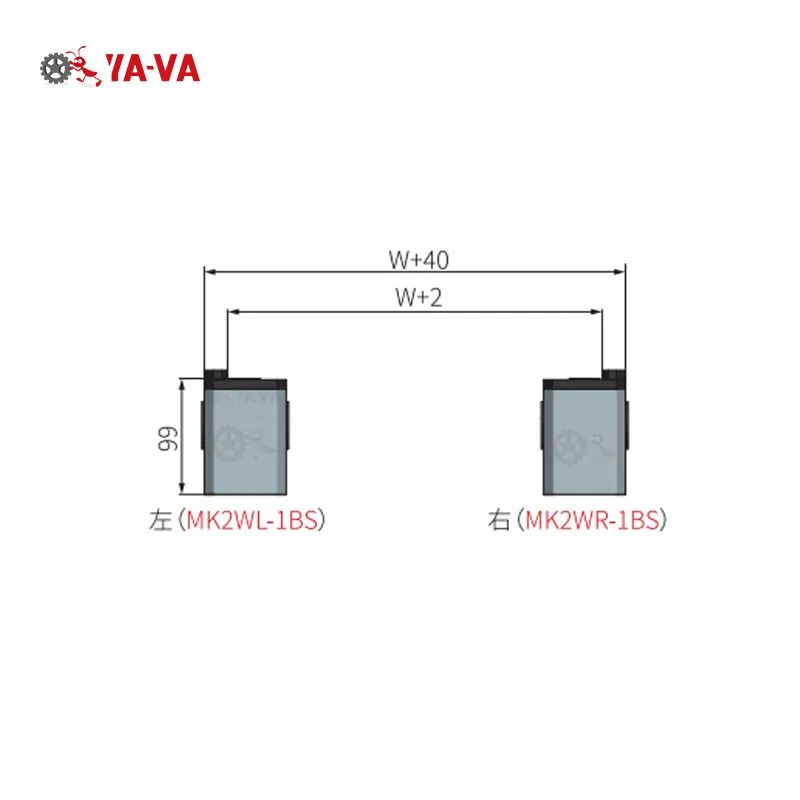

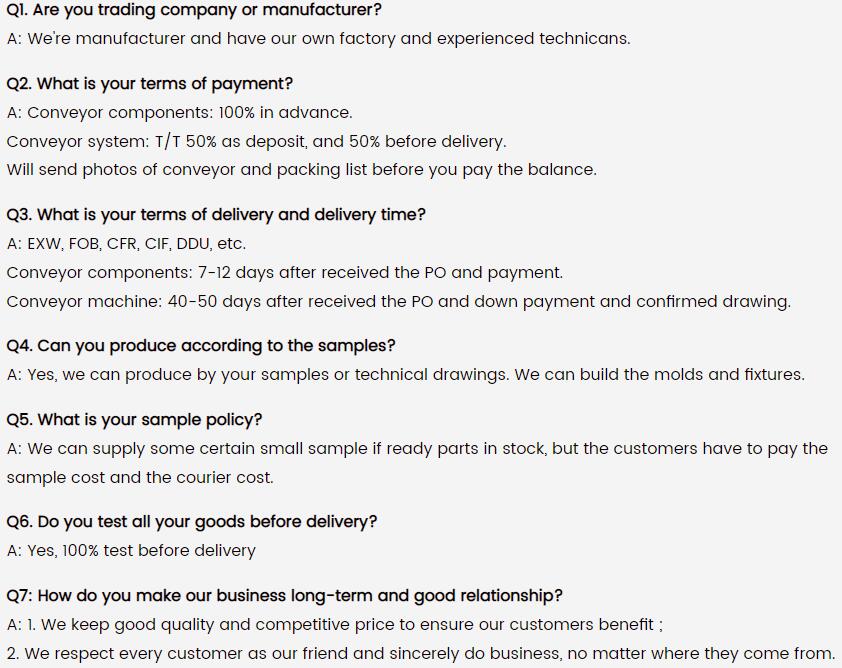

| Ntho | Boemo ba lebota | Bolelele ba pina bo sebetsang (mm) | Boima ba yuniti (kg) |

| MK2TL-1BS | Ka ho le lets'ehali | 3100 | 0.92 |

| MK2RL-1BS | Ka ho le letona | 0.92 |

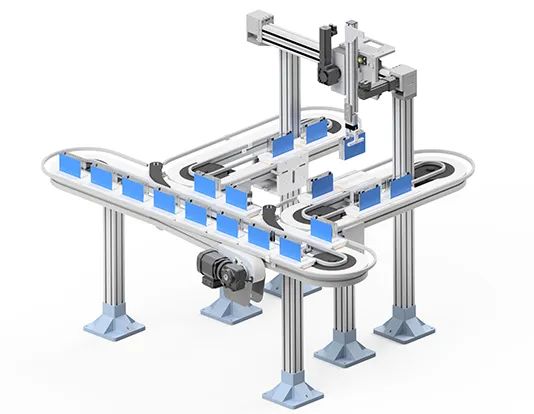

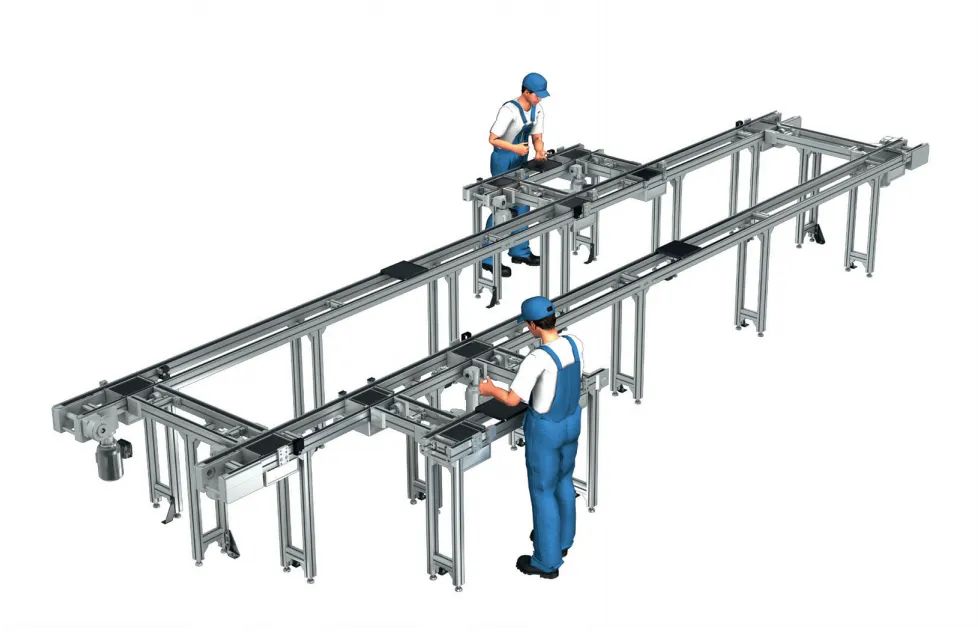

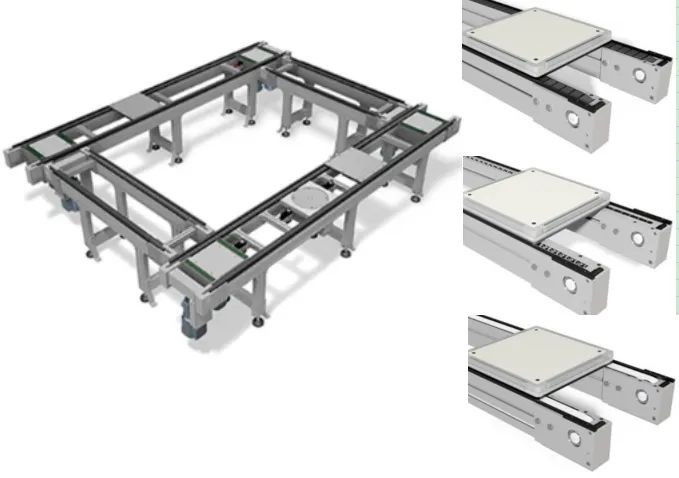

Li-conveyors tsa Pallet

Li-conveyors tsa Pallet ho latela le ho jara bajari ba lihlahisoa

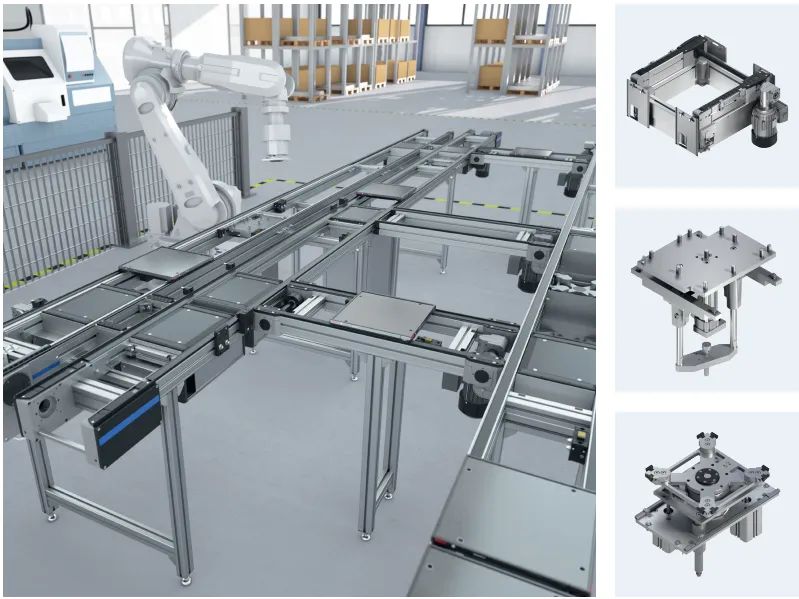

Li-conveyors tsa pallet li sebetsana le lihlahisoa ka bomong ho lijari tsa lihlahisoa tse kang liphalete.Pallet e 'ngoe le e' ngoe e ka ikamahanya le maemo a fapaneng, ho tloha kopanong ea lisebelisoa tsa bongaka ho isa tlhahiso ea likarolo tsa enjine.Ka tsamaiso ea pallet, u ka finyella phallo e laoloang ea lihlahisoa ka bomong ho pholletsa le ts'ebetso e feletseng ea tlhahiso.Li-pallets tse khethiloeng tse ikhethileng li lumella ho theha litsela tse itseng (kapa litlolo), ho latela sehlahisoa.

Ho ipapisitsoe le likarolo tse tloaelehileng tsa ketane ea li-conveyor, litsamaiso tsa pallet ea pina e le 'ngoe ke tharollo e sebetsang hantle ea ho sebetsana le lihlahisoa tse nyane le tse bobebe.Bakeng sa lihlahisoa tse nang le boholo bo boholo kapa boima ba 'mele, tsamaiso ea pallet ea mafahla ke khetho e nepahetseng.

Ka bobeli litharollo tsa pallet conveyor li sebelisa li-module tse hlophisehang tse etsang hore ho be bonolo le ho potlaka ho theha meralo e tsoetseng pele empa e otlolohile, e lumellang ho tsamaisa, ho leka-lekanya, ho buffer le ho beha liphalete.Khethollo ea RFID lipaleteng e thusa ho latela pina e le 'ngoe hape e thusa ho fihlela taolo ea lisebelisoa bakeng sa mohala oa tlhahiso.

1. Ke sistimi e fapaneng ea modular e fihlelang litlhoko tsa mefuta e mengata e fapaneng ea lihlahisoa.

2. Li fapane, li tiile, li tenyetseha;

2-1) mefuta e meraro ea li-conveyor media (mabanta a polyamide, mabanta a meno le liketane tsa ho bokella) tse ka kopantsoeng hammoho ho fihlela litlhoko tsa ts'ebetso ea kopano.

2-2) Litekanyo tsa pallets tsa mosebetsi (ho tloha ho 160 x 160 mm ho isa ho 640 x 640 mm) tse etselitsoeng boholo ba sehlahisoa.

2-3)Moroalo o phahameng o fihlang ho 220 kg ka phalete ea workpiece

3. Ntle le mefuta e fapaneng ea mecha ea phatlalatso ea conveyor, re boetse re fana ka lisebelisoa tse ngata tse khethehileng bakeng sa li-curve, li-conveyors tse pota-potileng, li-unit tsa boemo le li-drive unit.Nako le matsapa a sebelisitsoeng ho rala le ho rala li ka fokotsoa ho ba bonyane ho sebelisoa li-module tsa macro tse boletsoeng esale pele.

4.E sebelisoa ho indasteri e mengata, joalo ka indasteri e ncha ea matla, Likoloi, indasteri ea betri joalo-joalo

Lisebelisoa tsa Conveyor

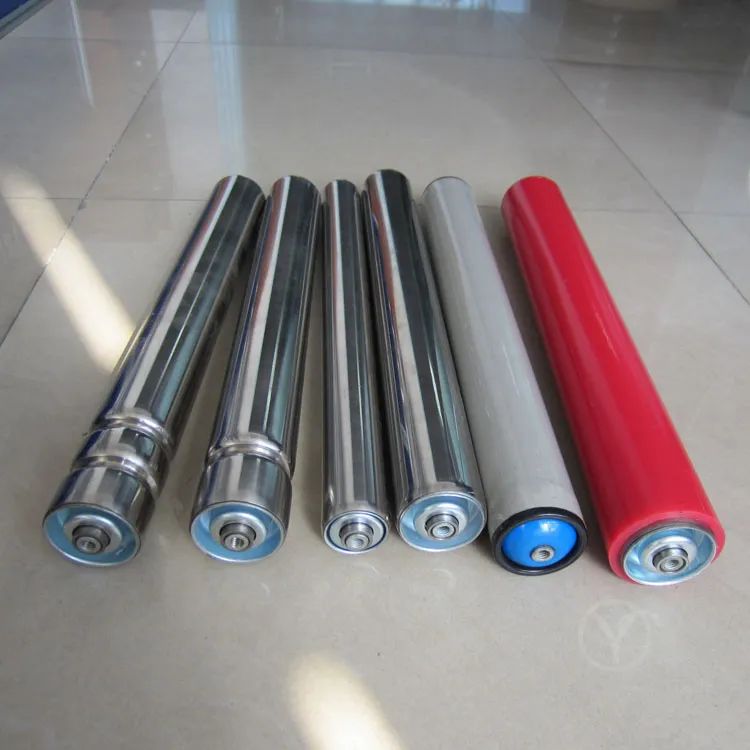

Likarolo tsa Conveyor: Lisebelisuoa tsa Modular lebanta le Chain, liporo tsa tataiso ea mahlakoreng, li-brackets tsa guie le li-clamp, hinge ea polasetiki, maoto a ho leka-lekanya, li-clamps tse kopanetsoeng, liphahlo, li-conveyor roller, tataiso ea li-roller, li-bearings joalo-joalo.

Likarolo tsa Conveyor: Likarolo tsa Aluminium Chain Conveyor System (boriti ba ts'ehetso, li-unit tsa ho qetela tsa koloi, bracket ea beam, beam ea conveyor, bend e otlolohileng, ho kobeha ha mabili, ho kobeha ho otlolohileng, likarolo tsa ho qetela tse sa sebetseng, maoto a aluminium joalo-joalo)

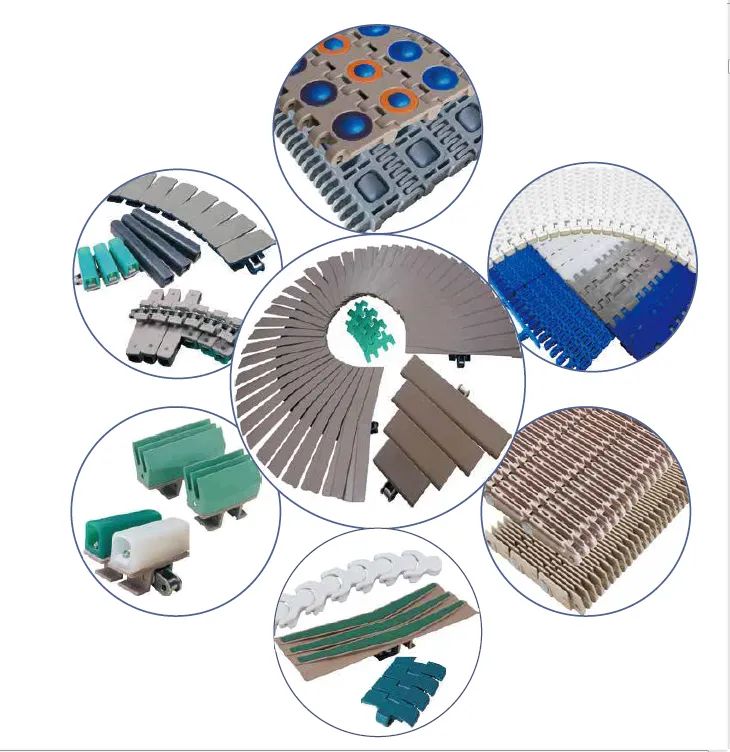

BELTS & CHAINS: E etselitsoe mefuta eohle ea lihlahisoa

YA-VA e fana ka mefuta e mengata e fapaneng ea liketane tsa conveyor.Mabanta le liketane tsa rona li loketse ho tsamaisa lihlahisoa le thepa ea indasteri efe kapa efe 'me li ka etsoa ka litlhoko tse fapaneng haholo.

Mabanta le liketane li na le likhokahano tse hokahaneng tsa polasetiki tse hokahaneng ka lithupa tsa polasetiki.Li lohiloe hammoho ka lihokelo ka mefuta e fapaneng ea boholo.Ketane kapa lebanta le kopaneng le etsa sebaka se sephara, se bataletseng le se thata sa conveyor.Ho na le mefuta e fapaneng ea bophara le bokaholimo ba lisebelisoa tse fapaneng.

Sehlahisoa sa rona se fana ka mefuta e fapaneng ea liketane tsa polasetiki, liketane tsa makenete, liketane tse kaholimo tsa tšepe, liketane tsa polokeho tse tsoetseng pele, liketane tse kolokileng, liketane tse pentiloeng, liketane tse holimo tse hohlang, liketane tsa rolara, mabanta a modular, le tse ling.Ikutloe u lokolohile ho ikopanya le rona bakeng sa lipuisano ho fumana ketane e loketseng kapa lebanta bakeng sa litlhoko tsa hau tsa tlhahiso.

Likarolo tsa Conveyor: Likarolo tsa Tsamaiso ea Li-Pallets ( lebanta la leino, lebanta le pharalletseng la matla a phahameng, ketane ea rolara, yuniti ea likoloi tse peli, yuniti e sa sebetseng, mochini oa ho roala, bracket ea agnle, maballo a tšehetso, leoto la tšehetso, maoto a feto-fetohang joalo-joalo.)

LBH

KE HOBANE'NG YA-VA

Setsebi:

Lilemo tse fetang 25 tse tsepamisitseng maikutlo ho nts'etsopele le nts'etsopele ea mochini oa lipalangoang oa R&D le tlhahiso, Kamoso e matla le e kholo ho feta tekanyo ea indasteri le mofuta.

E ka tšeptjoa:

Kholiseha ka botšepehi

Tsamaiso ea botšepehi, tšebeletso e ntle ho bareki

Mokitlane pele, boleng pele

Ka potlako:

Tlhahiso e potlakileng le phano, nts'etsopele ea khoebo e potlakileng

Lintlafatso le lintlafatso tsa sehlahisoa li potlakile, li kopana le tlhoko ea 'maraka ka potlako

Quick ke tšobotsi e hlahelletseng ea YA-VA

Mefuta-futa:

Letoto lohle la likarolo tsa conveyor le sistimi

Tharollo e akaretsang

Ts'ehetso ea boemo ba leholimo ka mor'a thekiso

Kopana le litlhoko tse fapaneng tsa bareki ka pelo eohle

Tharollo e le 'ngoe ea ho rarolla mathata ohle a bareki

E phahameng:

Boleng bo botle ke motheo oa boemo ba YA-VA.

Phehella boleng ba boleng bo holimo ba sehlahisoa e le e 'ngoe ea maano a bohlokoa a ts'ebetso le maano a ts'ebetso ea tlhahiso bakeng sa YA-VA.

Lisebelisoa tse tala tse khethiloeng tsa boleng bo holimo Laola ka thata boleng ba sehlahisoa, ka ntlafatso ea sistimi le ho itaea ka thata.

Ho se mamelle likotsi tsa boleng Ho sebeletsa boleng bo holimo, boikemisetso bo hlokolosi le bo hlokolosi