Likarolo tsa Sistimi ea Conveyor ea YA-VA tse Entsoeng Chaena

Lintlha tsa Bohlokoa

| Liindasteri tse Sebetsang | Mabenkele a ho Lokisa Mechini, Feme ea Tlhahiso, Fektheri ea Lijo le Lino, Reschorente, Lebenkele la Lijo, Mabenkele a Khatiso, Mabenkele a Lijo le Lino |

| Sebaka sa Pontšo | United States, Jeremane, Vietnam, Brazil, Indonesia, India, Mexico, Russia, Thailand, Korea Boroa |

| Boemo | E ncha |

| Thepa | Plastiki |

| Tšobotsi ea Boitsebiso | E hanela mocheso |

| Sebopeho | Sepalami sa lebanta |

| Sebaka sa Tšimoloho | Shanghai, China, Shanghai, China |

| Lebitso la Letšoao | YA-VA |

| Palo ea li-volts | 220V/318V/415V |

| Matla | 0.5-2.2KW |

| Tekanyo (L*W*H) | e etselitsoeng motho ka mong |

| Tiisetso | Selemo se le seng |

| Bophara kapa Bophara | 300mm |

| Tlaleho ea Teko ea Mechini | E fanoe |

| Tlhahlobo ea video e tsoang | E fanoe |

| Mofuta oa Papatso | Sehlahisoa se Tloaelehileng |

| Tiisetso ea likarolo tsa mantlha | Selemo se le seng |

| Likarolo tsa Bohlokoa | Enjene, Tse Ling, Bearing, Pompo, Gearbox, Enjene, PLC |

| Boima ba 'mele (KG) | 0.1 kg |

| Thepa ea Foreimi | SUS304/Tšepe ea Khabone |

| Ho kenya | Tlas'a Tataiso ea Tekheniki |

| Tšebeletso ea Kamora ho rekisa | Mechini ea Tšebeletso ea Baenjiniere ba Linaha Tse Ling |

| Nomoro ea Mohlala | UC/FU/FLU |

| Lebitso la Letšoao | YA-VA |

| Kopo | Mechine |

| Setifikeiti | ISO9001:2008; SGS |

Tlhaloso ea Sehlahisoa

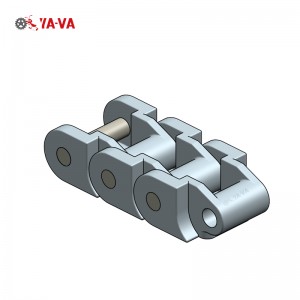

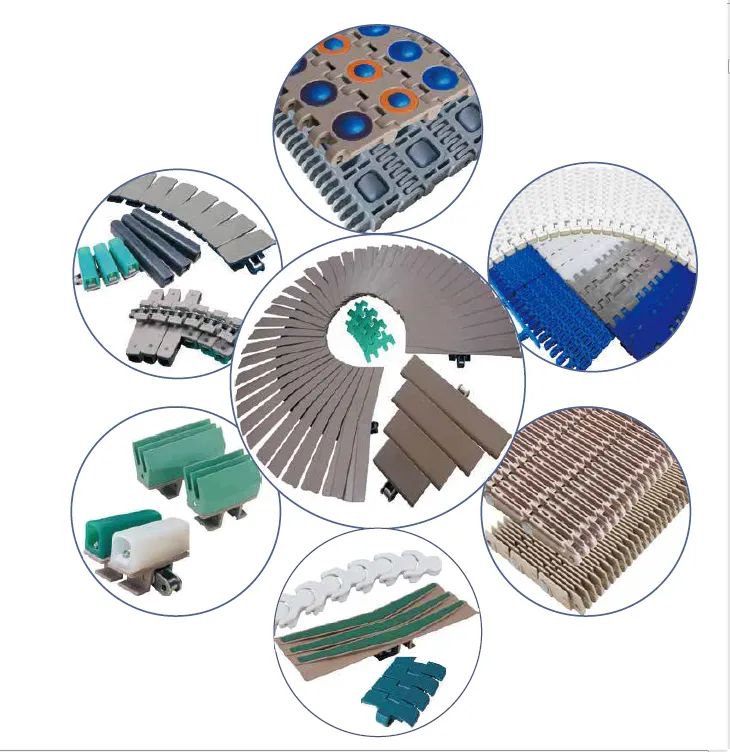

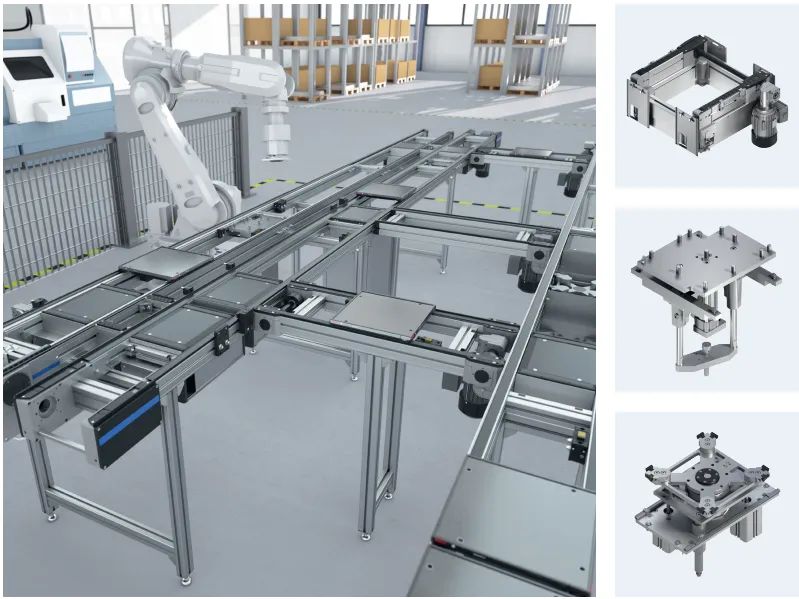

Likarolo tsa Conveyor: Lebanta la Modular le lisebelisoa tsa Ketane, lireile tsa tataiso ea lehlakore, libracket tsa guie le li-clamp, hinge ea polasetiki, maoto a ho lekalekanya, li-clamp tsa manonyeletso a sefapano, strip ea ho roala, roller ea conveyor, tataiso ea roller ea lehlakore, li-bearing le tse ling.

Likarolo tsa Conveyor: Likarolo tsa Sistimi ea Conveyor ea Chain ea Aluminium (boramo ba tšehetso, li-unit tsa ho qetela tsa drive, bracket ea boramo, boramo ba conveyor, kobeho e otlolohileng, kobeho ea mabili, kobeho e otlolohileng e otlolohileng, li-unit tsa ho qetela tsa idler, maoto a aluminium le tse ling)

MABANTLE LE LIKETANE: E etselitsoe mefuta eohle ea lihlahisoa

YA-VA e fana ka mefuta e mengata ea liketane tsa ho tsamaisa thepa. Mabanta le liketane tsa rona li loketse ho tsamaisa lihlahisoa le thepa ea indasteri efe kapa efe 'me li ka fetoloa ho latela litlhoko tse fapaneng haholo.

Mabanta le liketane li entsoe ka lihokelo tsa polasetiki tse hoketsoeng ka lithupa tsa polasetiki. Li lohiloe hammoho ka lihokelo ka tekanyo e pharaletseng. Ketane kapa lebanta le kopaneng le etsa bokaholimo bo pharaletseng, bo bataletseng le bo tiileng ba conveyor. Bophara le libaka tse fapaneng tse tloaelehileng bakeng sa lits'ebetso tse fapaneng lia fumaneha.

Tlhahiso ea rona ea lihlahisoa e fapana ho tloha ho liketane tsa polasetiki, liketane tsa makenete, liketane tsa tšepe tse ka holimo, liketane tse tsoetseng pele tsa polokeho, liketane tse kopaneng, liketane tse qhetsoeng, liketane tse ka holimo tse khohlanong, liketane tsa roller, mabanta a modular, le tse ling. Ikutloe u lokolohile ho ikopanya le rona bakeng sa puisano ho fumana ketane kapa lebanta le loketseng litlhoko tsa hau tsa tlhahiso.

Likarolo tsa Conveyor: Likarolo tsa Sistimi ea Conveyor ea Lipaleti (lebanta la meno, lebanta le bataletseng la phetiso ea matla a phahameng, ketane ea roller, yuniti ea ho khanna habeli, yuniti ea idler, strip ea ho roala, bracket ea agnle, maballo a tšehetso, leoto la tšehetso, maoto a fetoloang le tse ling.)

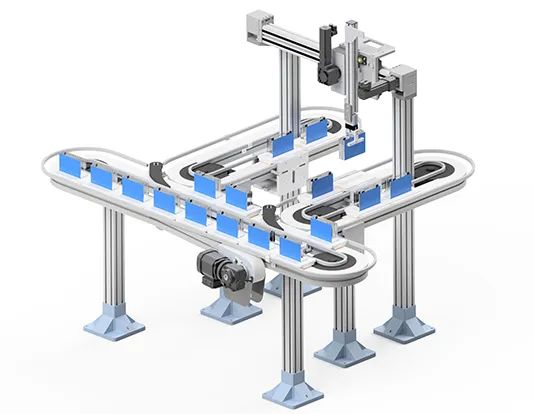

Sejana sa Spiral Flex

Li-conveyor tse potolohang li eketsa sebaka se fumanehang sa tlhahiso fatše

Tsamaisa lihlahisoa ka ho otloloha ka tekanyo e phethahetseng ea bophahamo le sebaka seo u ka se nkang.

Li-conveyor tse potolohang li phahamisa mohala oa hau ho ea boemong bo bocha.

Ho phahamisa tsamaiso ea lihlahisoa

Morero oa sesebelisoa sa ho tsamaisa lifti se potolohang ke ho tsamaisa lihlahisoa ka ho otloloha, ho koala phapang ea bophahamo. Sesebelisoa sa ho tsamaisa se potolohang se ka phahamisa mohala ho etsa sebaka mokatong oa tlhahiso kapa sa sebetsa e le sebaka sa buffer. Sesebelisoa sa ho tsamaisa se bōpehileng joaloka spiral ke senotlolo sa kaho ea sona e ikhethang e nyane e bolokang sebaka sa bohlokoa sa mokatong.

Litharollo tsa rona tsa ho phahamisa li-spiral li sebetsa hantle haholo meleng ea ho tlatsa le ho paka. Litšebeliso tse ka bang teng tsa li-spiral li tloha ho sebetsana le liphutheloana kapa li-tote ka bonngoe ho isa linthong tse kang liphutheloana tsa libotlolo tse phuthetsoeng ka mokhoa o fokolang kapa mabokose.

Melemo ea bareki

Sebaka se senyenyane sa maoto

Modular & maemo a tloaelehileng

Ho sebetsana le sehlahisoa ka bonolo

Boemo ba lerata bo tlase

Litlhophiso tse fapaneng tsa infeed le outfeed

Ho phahama ho fihlela ho limithara tse 10

Mefuta e fapaneng ea ketane le likhetho

Bolelele bo phahameng ka ho fetisisa holim'a sebaka se senyenyane sa maoto

Lifti e potolohang ke tekanyo e phethahetseng ea bophahamo le sebaka sa maoto, e kopantsoeng le lebelo le pharaletseng le le tenyetsehang.

Li-conveyor tsa rona tse bōpehileng joaloka spiral li netefatsa phallo ea sehlahisoa e tsoelang pele ha bophahamo bo le bonolo ebile bo tšepahala joaloka conveyor e tloaelehileng e otlolohileng.

Ho kenya habonolo le ts'ebetso e se nang mathata

Lifti ea YA-VA spiral ke module e sebetsang ka botlalo eo ho leng bonolo ho e etsa ho latela litlhoko tsa hau. E na le ketane e holimo ea polasetiki e nang le khohlano e phahameng e nang le li-bearing tse kopantsoeng motheong oa ketane ea tšepe, e tsamaeang khahlanong le seporo sa tataiso se ka hare. Tharollo ena e netefatsa hore ho sebetsa hantle, lerata le tlaase le bophelo bo bolelele ba tšebeletso. Ho fetisetsa le ho tsoa ho li-conveyor tse hokelang ho etsoa hore ho be bonolo ka likarolo tse otlolohileng tsa ho kena le tsa ho ntša. Li-conveyor tsa rona tsa spiral ke tharollo e phethahetseng bakeng sa ho phahamisa kapa ho theola:

Lihlahisoa tse pakiloeng kapa tse sa pakoang

Bajari ba lihlahisoa tse kang li-puck kapa mabokose

Mabokose a manyane, liphutheloana le mabokose

Lifti e nyane ea Spiral - ho ea holimo le tlase ka morero

Tharollo ea rona e fokolang ea ho phahamisa leoto, lifti ea Compact Spiral, e eketsa phihlello ea hau mokatong oa tlhahiso le sebaka se fumanehang. Ka bophara ba 750 mm feela, sehokelo se ikhethang sa lifti sa Compact Spiral se fana ka leoto le lenyenyane ka 40% ho feta litharollo tse tloaelehileng haholo 'marakeng. E lumella bahlahisi ho eketsa haholo sebaka sa fatše sa tlhahiso se fumanehang ka ho phahamisa le ho theola lihlahisoa ho fihlela ho 10000 mm holim'a fatše.

Lifti e Nyenyane ea Sepekere e tsoang ho YA-VA e etselitsoe ho lekana mohala oa hau oa tlhahiso o seng o ntse o le teng. Ho kopanngoa ha li-conveyor tse peli tse nyane tsa sepekere ho fana ka sebaka bakeng sa liforoko tsa hau. Sepekere sa rona se tloaelehileng le sa modular se loketse ho sebetsa ka mor'a lihora tse 'maloa. E boetse e netefatsa hore e sebetsa hantle, e na le lerata le tlase, 'me e phela nako e telele.

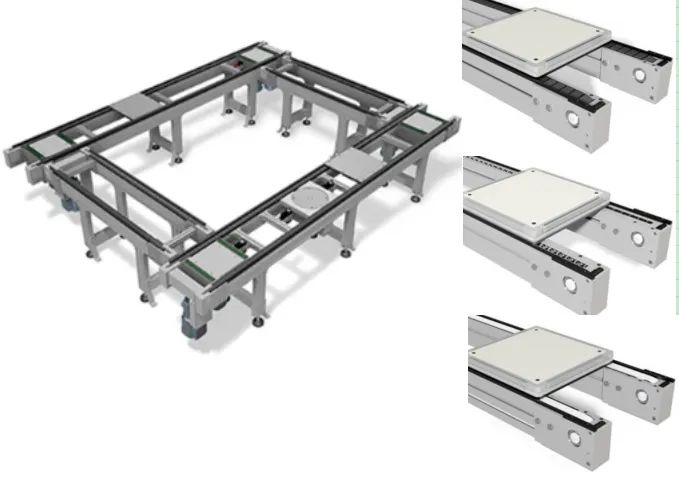

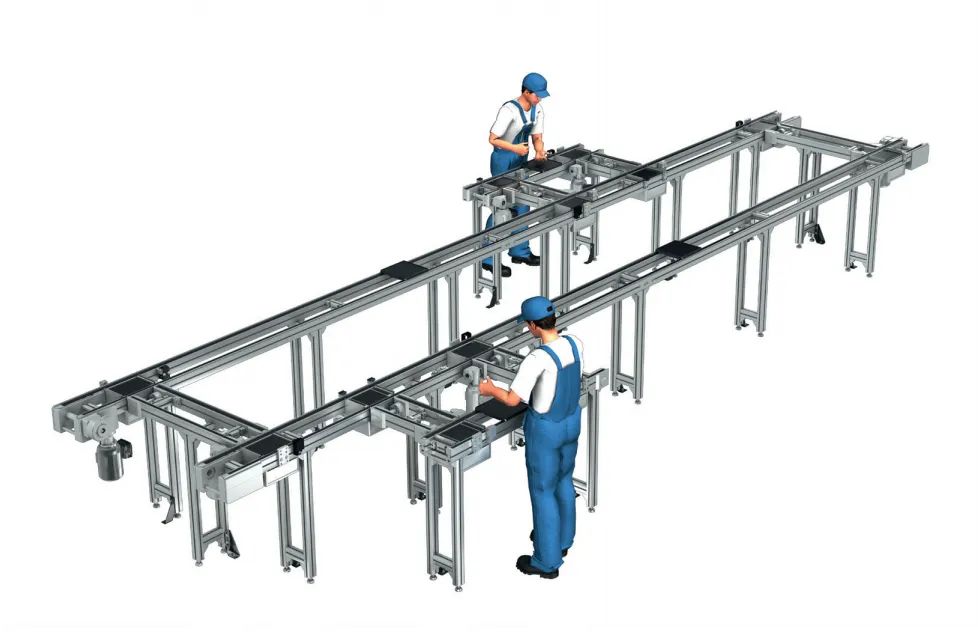

Li-conveyor tsa Pallet

Li-conveyor tsa pallet ho latela le ho jara bajari ba lihlahisoa

Li-conveyor tsa pallet li sebetsana le lihlahisoa ka bomong ho lijari tsa lihlahisoa tse kang li-pallet. Pallet ka 'ngoe e ka fetoloa ho latela maemo a fapaneng, ho tloha kopanong ea lisebelisoa tsa bongaka ho ea tlhahisong ea likarolo tsa enjene. Ka sistimi ea pallet, u ka fihlella phallo e laoloang ea lihlahisoa ka bomong nakong eohle ea ts'ebetso e felletseng ea tlhahiso. Li-pallet tse ikhethileng tse khethiloeng li lumella ho theha litsela tse itseng tsa ho tsamaisa (kapa diresepe), ho latela sehlahisoa.

Ho latela likarolo tse tloaelehileng tsa ketane ea ho tsamaisa thepa, litsamaiso tsa pallet tse nang le tsela e le 'ngoe ke tharollo e theko e tlaase ea ho sebetsana le lihlahisoa tse nyane le tse bobebe. Bakeng sa lihlahisoa tse nang le boholo kapa boima bo boholo, sistimi ea pallet e nang le tsela e le 'ngoe ke khetho e nepahetseng.

Litharollo ka bobeli tsa ho tsamaisa lipalete li sebelisa li-module tse tloaelehileng tse ka hlophisoang tse etsang hore ho be bonolo le ho potlaka ho theha meralo e tsoetseng pele empa e le bonolo, e lumellang ho tsamaisa, ho leka-lekanya, ho buffer le ho beha lipalete sebakeng se le seng. Ho tsebahatsa RFID ka har'a lipalete ho nolofalletsa track-and-trace ea karolo e le 'ngoe 'me ho thusa ho fihlella taolo ea thepa bakeng sa mohala oa tlhahiso.

1. Ke sistimi e fapaneng ea modular e fihlelang litlhoko tsa mefuta e mengata ea lihlahisoa tse fapaneng.

2. E fapane, e tiile, e tenyetseha;

2-1) mefuta e meraro ea mecha ea phatlalatso ea conveyor (mabanta a polyamide, mabanta a meno le liketane tsa li-roller tse bokellanang) tse ka kopanngoang hammoho ho fihlela litlhoko tsa ts'ebetso ea kopano

2-2) Litekanyo tsa lipallet tsa mosebetsi (ho tloha ho 160 x 160 mm ho fihlela ho 640 x 640 mm) tse etselitsoeng boholo ba sehlahisoa ka ho khetheha

2-3) Mojaro o phahameng o phahameng oa ho fihlela ho 220 kg ka pallet ea mosebetsi

3. Ntle le mefuta e fapaneng ea mecha ea phatlalatso ea conveyor, re boetse re fana ka bongata ba likarolo tse itseng bakeng sa li-curve, li-transverse conveyor, li-setting unit le li-drive unit. Nako le boiteko bo sebelisoang ho rala le ho rala li ka fokotsoa ho sebelisoa li-macro module tse hlalositsoeng esale pele.

4. E sebelisoa indastering e mengata, joalo ka indasteri ea matla a macha, Likoloi, indasteri ea betri le tse ling

Ho paka le ho Romela

Bakeng sa likarolo, ka hare ho na le mabokose a lebokose mme ka ntle ho na le lebokose la pallet kapa la lehong la ply-wood.

Bakeng sa mochini o tsamaisang thepa, o tletse mabokose a plywood ho latela boholo ba lihlahisoa.

Mokhoa oa ho romela thepa: ho latela kopo ea moreki.

LBH

P1. Na o rekisa k'hamphani kapa moetsi?

K: Re baetsi mme re na le fektheri ea rona le litsebi tsa theknoloji tse nang le boiphihlelo.

P2. Melao ea hau ea tefo ke efe?

A: Likarolo tsa Conveyor: 100% esale pele.

Sistimi ea conveyor: T/T 50% e le depositi, le 50% pele ho pepa.

E tla romela linepe tsa lenane la thepa e tsamaisang thepa le la ho paka pele o lefa tjhelete e setseng.

P3. Lipehelo tsa hau tsa ho tlisa thepa le nako ea ho e tlisa ke life?

A: EXW, FOB, CFR, CIF, DDU, joalo-joalo.

Likarolo tsa conveyor: Matsatsi a 7-12 kamora ho fumana PO le tefo.

Mochini oa ho tsamaisa thepa: Matsatsi a 40-50 kamora ho fumana PO le tefo ea pele le ho tiisa ho hula.

P4. Na o ka hlahisa ho latela disampole?

K: E, re ka hlahisa ka disampole tsa hao kapa ka ditshwantsho tsa botekgeniki. Re ka haha dibopeho le disebediswa.

P5. Leano la hau la mohlala ke lefe?

K: Re ka fana ka sampole e itseng e nyane haeba likarolo li se li loketse ho ba teng setokong, empa bareki ba tlameha ho lefa litšenyehelo tsa sampole le litšenyehelo tsa ho romella thepa.

P6. Na o leka thepa yohle ya hao pele o e tlisa?

A: E, teko ea 100% pele ho pepa

P7: U etsa joang hore khoebo ea rona e be ea nako e telele le kamano e ntle?

K: 1. Re boloka boleng bo botle le theko e hlōlisanang ho netefatsa hore bareki ba rona ba rua molemo;

2. Re hlompha moreki e mong le e mong e le motsoalle oa rona 'me re etsa khoebo ka tieo, ho sa tsotelehe hore na ba tsoa hokae.