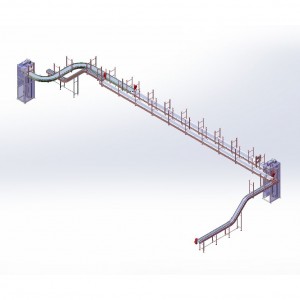

tsela ea ho retelehela ea conveyor—— tsela ea sekhutlo

Tlhaloso ea Sehlahisoa

Likaroloana:

1. Moralo oa tsela ea ho reteleha o entsoe ho netefatsa phetoho e boreleli bakeng sa lebanta la conveyor kapa lirolara ha li ntse li tsamaea likhutlong kapa likhutlong, ho fokotsa kotsi ea tšenyo ea sehlahisoa le ho boloka phallo e tsitsitseng ea thepa.

2. Litsela tsa ho reteleha li fumaneha ka boholo bo fapaneng ba radius le likhutlo ho amohela litlhophiso tse fapaneng tsa sebopeho le lithibelo tsa sebaka ka har'a setsi.

3. Litsela tsa ho reteleha li etselitsoe ho lumellana le litsamaiso tse itseng tsa lebanta la ho tsamaisa kapa lirolara, ho netefatsa hore ho na le ho lumellana ho nepahetseng le ho kopanngoa le likarolo tse teng tsa ho tsamaisa.

4. Likarolo tsa tsela e retelehang li hahiloe ho fana ka botšepehi ba sebopeho le tšehetso bakeng sa sistimi ea conveyor, ho boloka botsitso le ho lumellana nakong ea liphetoho tsa tataiso.

5. Litsela tsa ho reteleha li ka etsoa hore li lumellane le litlhoko tse itseng tsa sistimi ea ho tsamaisa thepa, ho kenyeletsoa le bokhoni ba ho kopanya likarolo tse otlolohileng, ho kopanya le ho arohana, ho ntlafatsa phallo ea thepa ka har'a setsi.

6.Literata tsa ho retoloha li etselitsoe ho amohela mefuta e fapaneng ea lihlahisoa le meroalo, ho netefatsa hore sistimi ea ho tsamaisa thepa e ka sebetsana le thepa e fapaneng ka katleho ha e ntse e tsamaea likhutlong kapa likhutlong.

Sehlahisoa se Amanang

Sehlahisoa se seng

mohlala oa buka

Selelekela sa khamphani

Selelekela sa khamphani ea YA-VA

YA-VA ke moetsi ea ka sehloohong oa litsebi bakeng sa sistimi ea conveyor le likarolo tsa conveyor ka lilemo tse fetang 24. Lihlahisoa tsa rona li sebelisoa haholo lijong, lino tse tahang, litlolo, thepa, ho paka, khemisi, boiketsetso, lisebelisoa tsa elektroniki le likoloi.

Re na le bareki ba fetang 7000 lefatšeng ka bophara.

Seboka sa 1 ---Fektheri ea ho Enta ka Ente (e etsang likarolo tsa conveyor) (10000 Square meter)

Workshop 2--Fektheri ea Sistimi ea Conveyor (mochini oa tlhahiso ea conveyor) (10000 Square meter)

Kopano ea likarolo tsa polokelo ea matlo a mararo le tsa conveyor (10000 Square meter)

Fektheri ea 2: Motse oa Foshan, Profinseng ea Guangdong, e sebeletsoa bakeng sa 'Maraka oa rona oa Boroa-Bochabela (5000 Square meter)

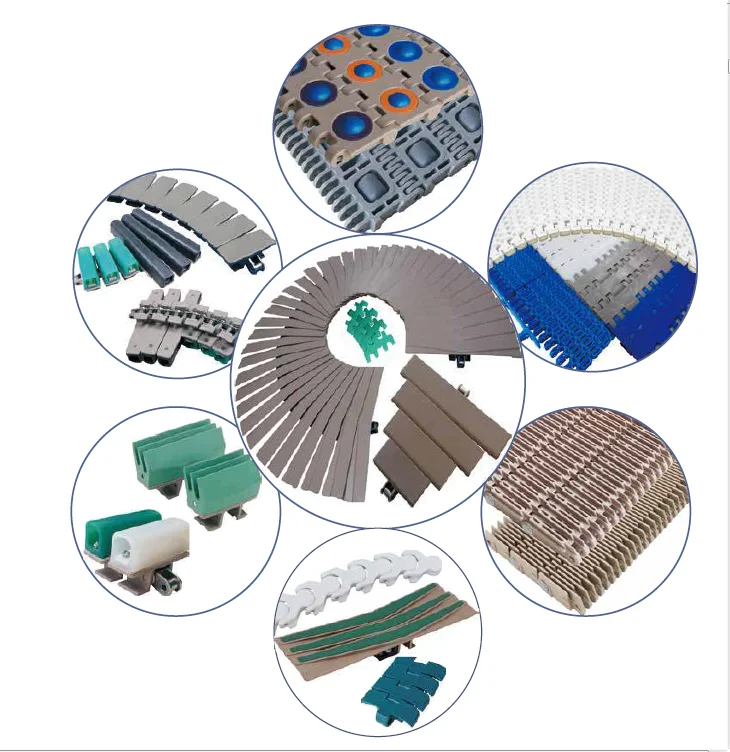

Likarolo tsa Conveyor: Likarolo tsa Mechini ea polasetiki, Maoto a ho lekalekanya, Mabakete, Moqhaka oa ho roala, Liketane tse bataletseng, Mabanta a Modular le

Li-sprocket, Conveyor Roller, likarolo tse tenyetsehang tsa conveyor, likarolo tse tenyetsehang tsa tšepe e sa ruseng le likarolo tsa pallet conveyor.

Sistimi ea Conveyor: conveyor e potolohang, sistimi ea conveyor ea pallet, sistimi ea conveyor ea tšepe e sa hloekang, conveyor ea ketane ea slat, conveyor ea roller, conveyor ea lebanta, conveyor e nyolohang, conveyor ea grip, conveyor ea lebanta la modular le mohala o mong oa conveyor o ikhethileng.